- 3-capa plantas productoras de folios (18)

- Extrusoras (27)

- Extrusoras de doble husillo (36)

- Extrusoras de película plana (4)

- Extrusoras de un solo husillo (34)

- Instalaciones de extrusión de láminas planas (5)

- Instalaciones de películas sopladas (6)

- Instalaciones de regranulado (35)

- Líneas de extrusión (21)

- Líneas de extrusión para tuberías (12)

- Plantas de coextrusión (11)

- Plantas de granulado (19)

- Sistemas de perfiles (7)

- Sistemas de perfiles y plantas de extrusión (11)

- más

- ABB (1)

- AGRIFON (4)

- ALLWEILER (1)

- ALPHATEC (2)

- Amut (10)

- Ankele (2)

- APV (1)

- ART PLASTICS RECYCLING T (1)

- Artec (3)

- ATA MACHINERY (1)

- AUTOMATIK (1)

- AVITA (1)

- BANDERA (28)

- BANDERA - REIFENHäUSER (1)

- BANDERA E TPV (1)

- BARMAG (1)

- BARMEG (1)

- BARWELL (1)

- Battenfeld (11)

- BATTENFELD-CINCINNATI (1)

- BATTENFELD-ESDE-GRAEWE (1)

- BAUSANO (2)

- Berstorff (4)

- BERSTORFF GMBH (1)

- BERSTORFF KRAUSS MAFFEI (1)

- BETOL (1)

- BIELLONI (1)

- BKG (1)

- BKG NORDSON (1)

- BLAKE (1)

- BLASKOPF (1)

- BRABENDER (1)

- BREYER (1)

- BRITAS (1)

- BRüCKNER (1)

- BUSS (1)

- CALENDER (1)

- CALINI , (1)

- CAPUZZI (1)

- CDM OMP-PREALPINA (1)

- CDM PREALPINA (1)

- CHANGZHOU SCHUANGLI (1)

- China (3)

- Cincinnati (8)

- CINCINNATI -TECNOMATIC-SICA (1)

- CINCINNATI MILACRON (1)

- CMG (2)

- COLINES (1)

- COLLIN (1)

- COLOURMAT (1)

- Comac (3)

- COPERION (1)

- COPERION WERNER + PFLEIDE (1)

- COPERION WERNER PFLEIDERER (1)

- COPERION WERNER+PFLEIDERE (1)

- COVEX (1)

- COVEX EXTRUSORAS (1)

- CRESPI (1)

- D EVO (1)

- DAVIS-STANDAR (1)

- DEA (HEXAGON) (1)

- DEACHANG MACHINERY (1)

- DING KUEN (2)

- DR. COLLIN (1)

- EDI (2)

- EKOCHEM (1)

- EREMA (19)

- EREMA GROUP UMAC (1)

- ERMAFA RECYCLING (1)

- EUROTECNO (3)

- EXTRAPLAST MACHINEN GMBH (1)

- FALZONI (2)

- FARE (1)

- FAT (1)

- Feddem (2)

- FONG KEE (1)

- FRANCIS SHAW (1)

- Future Tech (2)

- GAMMA MECCANICA (1)

- GAMMAMECCANICA (2)

- GENERAL PLASTICS (1)

- GENG-MAYER (1)

- GERMANPLAST (4)

- GHIOLDI (2)

- GREINER (1)

- GWELL (1)

- GöTTFERT (1)

- HEDELIUS (1)

- HERKULES (1)

- HORSRIDER MACHINERY - COMPLETE WORKING M (1)

- IBAÑEZ (1)

- IBAÑEZ EXTRUSORAS (1)

- ICMA SAN GIORGIO (2)

- IDDON (1)

- IDE (6)

- ITALIAN (3)

- Jwell (2)

- KELLER (1)

- KNOLL (1)

- Krauss Maffei (5)

- ... más

Fabricante:

(Categoría: 302)

weight max.: 20 taxial load -forward: 9 taxis load in the back: 9 tBrake system: size of tire: 550/45-22,5 total power requirement: kWweight of the machine ca.: tdimensions of the machine ca.: mThe data for this ad was created with ModulMWS - the software solution of LogoTech oHG. ... más información

Año de construcción: 1992

usado

A used, non-refurbished extrusion recycling brand EREMA Type 1007 TVE for processing polyethylene (PE) and polypropylene (PP), for processing printed films. Fully equipped. The machine is located in a production plant. Power HD-PE 250 -300 kg/h, PE LD and PP300 - 350 kg/h, electrics 240/400 volts, 50 hearts, available at short notice. Auch + Technik e. Kfm. D-73728 Esslingen Phone +0049 1577 5329827

We offer directly on behalf of the owner : Twin-screw extruder Make : COPERION ( Werner & Pfleiderer ) Gearbox make : P.I.V Type : ZSK 170 W 1920/1750 Year of construction : 2021 / 2002 / 1986 Screw diameter : 172 mm Screw speed : 4,9 - 49 min-1 Max. torque : 17,500 Nm Main engine : 216 kW In the last 3 years, a total of over €420,000 has been invested in new components and factory overhauls (some of which were previously unused) The extruder was in use until Aug / 2023 and has already been dismantled ready for transport. The components are partly redundant and date from the years 1986 - 2021. The scope of delivery consists of : Twin screw degassing Coperion DSE 180 - 1 x year of manufacture 2021 ( 180 t€ ) Main gearbox P.I.V - 1 x year of manufacture 2002, factory overhauled ( 233 t€ ) in 2021, unused - 1 x year of manufacture 1986, factory o ...

x-travel: 3000 mmy-travel: 2500 mmz-travel: 1000 mmControl: Siemens type: 840 DFeed: 5-30.000 mm/minTable area: 2000x2170 mmtable load: 1500 Kg/m²T-slots: 22 H9distance between uprigths: 2500 mmspindle turning speed range: 6000 U/minspindle drive: 36 kWspindle taper: HSK 100Tool changer: 30 total power requirement: kWweight of the machine ca.: tdimensions of the machine ca.: 8x6,4x4,4 mThe data for this ad was created with ModulMWS - the software solution of LogoTech oHG.

GAMMA MECCANICA EXTRUDER, Material rigid HDPE + PP, LDPE, Nominal Output HDPE+PP 1.800 kg/h, LDPE+PP 1.400 kg/h, Screw diameter 250 mm 24 L/D, BDPLAST semi-automatic screenchanger (available with fully automatic screenchanger on request), Water ring Pelletizer Gamma Meccanica, Drying centrifuge Gamma Meccanica, vibrating screen, The line is offered AS IS or RECONDITIONED

GWELL GWC 80-156 WPC production line manufactured in 2015 is characterised by high production efficiency. WPC boards are made by combining natural components with thermoplastic polymers. This results in a material with the high aesthetics of wood and the exceptional durability of plastics, distinguished by full resistance to fungus, insects and various atmospheric factors. The production line consists of: – GWC 80/156 twin-screw extruder – GWC 65/132 twin-screw extruder – CUT 240 saw – CAL 14000/6 calibrating table – ROL 240 2-caterpillar haul-off – unloading table The WPC profile extrusion line is offered with optional heads for forming different types of profiles from these products. To date, the machine has only been in operation for a dozen days and has not been used at full production scale. For an additional charge, equipment cooperating with the line can ...

Extruder 1 screw: 70 Ø diam, 35 L/D. Brand: Flag, engine: 37 KW (50 hp). No electrical panel. Ready to get started? Contact us directly! Send us a WhatsApp message to (+34) 647 590 257 or an email to infogester.es for personalized advice. ... más información

x-axis: 700 mmy-axis: 1.000 mmz-axis: 500 mmmax. table load: 900 kgtotal power requirement: kWweight of the machine ca.: tdimensions of the machine ca.: m3D coordinate measuring machine- PC with software, various probes- Renishaw PH10MQSoftware: PC-DMIS Pro 3.7 Maintenance Release 2The data for this ad was created with ModulMWS - the software solution of LogoTech oHG.

VARIOUS SIZES AVAILABLE, Example : for a 250 mm. screen Ø:, Single plate with 2 sliding breakers with radial holes 6,5 mm.diam. Screen diam.250 mm. Construction in steel on n.1 supporting wheeled cart Heating through 4 plate heaters W 3.750 V.240 each one Total power 23 Kw Hydraulic l power station 7,5 kw with control electrovalves, n.2 storage units Pump group externally positioned PTFE ring N.2 temperature controls on drawers N.2 temperature controls on bodies Max work temperature 260 °C Complete with all safety devices Control panel on hydraulic pack Pressure transducer User’s manuals, drawings CE, TYPE: Semi-automatic, non-stop

For LDPE MDPE and BIO Web width from 600 mm up to 1600 mm Throughput rate 100/160 kg/h depending on materials Max production speed 80 Min/max thickness 30/200 my (tolerance sigma 2 +/- 8% Extruder with screw diam. 65 mm. 30 L/D MELT control Oscillating die diam. 100-200-300 mm. gap 1,4 mm. Blow Up Ratio 1,5 – 4,5 high capacity cooling ring with inverter on electric fan 7,5 kw Calibrating basket 1.000 max diam. Gusseting units Pull off unit min/max width 600_1600 mm. Stretching rollers 1.800 mm wide Corona treatment Back to back winding station type BA 2/1.800 Max reel diam. 1000 mm. N.2 slit and seal units Supporting tower height approx 9,0 mt. Construction year 2003 Excellent conditions Mounted but disconnected

MP BLOWN FILM EXTRUDER EBHD 80, for HDPE and LDPE, constructed in 2005, excellent conditions, Barrel Screw: Φ80 mm with mixing zone LD 28/1 nitride hard chromium steel, Barrel heating zones: 4 zones thermal power 4 KW each plus 1 filter thermal zone 4 KW., Screw Length (L/D) : 28/1, Screw Diameter (mm): 80, Screw Speed (R.P.M.) : 65, Cylinder Total Heating (KW): 16, Flange Heating (KW): 4, Number of Die Heating Zones: 3, Die Total Heating (KW): 6,6, Cylinder Cooling: 4 separates fan motors for each individual thermal zone, Cylinder Cooling Power (KW): 3,5, Installed Electric Power (KW): 70, Max Output (KG/H): LDPE 100 Kg/H, HDPE 90 Kg/h, Film Width: (Min-Max) 280 mm – 1000 mm, Film Thickness: (Min-Max) 0,018-0,200 mm, Main Driving Gear Reducer: Monobloc Reducer Italy Made ROSSI SPA”, Main Motor: AC 3 Phase Inductance Motor 30 KW (40 HP)., Main Motor Control Driving: (VFD Inverter MI ...

Inv. Num. : 7235 Type: 6.5 Producer: Weber Generated: Parameters: Equipment: Calibration table ? Tow strap ... más información

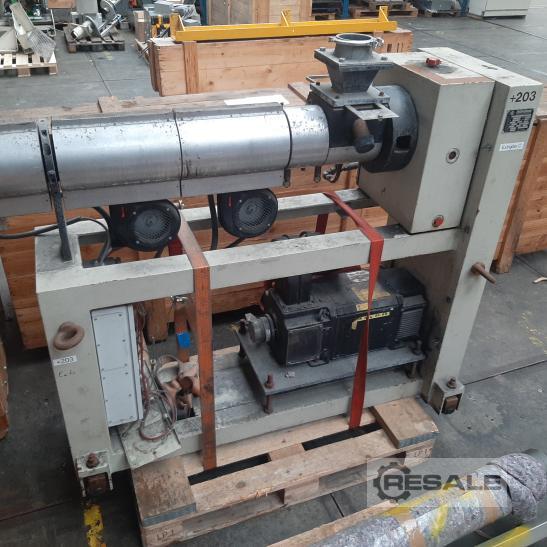

used REIFHÄUSER single screw extruder with screw size: diameter 35mm / 25 ld The extruder is in very good condition Type RT 78-1-35-25 New control cabinet with new motor AC -7,5kW Year of construction 1994 Quickly available ... más información

Used extruder in good condition with screw size: diameter 50 mm x 30v grooved intake and degassing zone Type RH 241-1-50-30v with DC drive 30.2 kW Built in 1993 Immediately available without control cabinet With control cabinet 4-6 weeks delivery time ... más información

TECNOVA EXTRUSION LINE 130 mm.500 kg/h, PE PP PC PS ABS PET PA, Including:, Scrap silo, Extraction auger, Crammed feeder, Extruder with 130 mm screw diam.37 L/D, N. 1 vacuum degassing pump, 225 kw drive, Semi-automatic non stop screen-changer with screens diam.250 mm., Available with a [FIMIC RAS 400](https://www.germanplast.eu/listings/5241333-used-2007-fimic-ras-4 00-automatic-screenchanger), Water ring pelletizer, Drying centrifuge, Pneumatic extraction for granulate, Constructed in 2004, not working from 2010, Offered reconditioned (various steps to be agreed upon), (see how we recondition on our WHAT WE DO page on top)

Extruder 1 spindle Brand: Bandera, 80 Ø diám 25L/D, with two speeds, alternating current motor: 55 kw (75 hp) with variable speed drive. Two replacement spindles, one for rigid PVC and one for plasticized PVC. Ready to get started? Contact us directly! Send us a WhatsApp message to (+34) 647 590 257 or an email to infogester.es for personalized advice.

Extruder 1 screw: 60 mm Ø, 25 L/D, brand: Flag, motor: 11 KW (15 hp). 6-speed gearbox with electrical panel. Ready to get started? Contact us directly! Send us a WhatsApp message to (+34) 647 590 257 or an email to infogester.es for personalized advice. ... más información

PVC sheet extrusion line with head: 280mm, composed of: - 2-screw extruder, brand: Weber, model: DS.8.22, motor: 30 Kw (40 hp), load doser, degasser with vacuum pump. Variable speed drive and electrical panel. - Wide blade head: 280 mm. - Calender, width: 300 mm, diameter: 150 mm. 3 water-cooled rollers. With stretching. - Ink baths, dryer, stretch for several coats of paint. - Cutting shear. - 1-reel winder, width: 300 mm. - Various replacement rollers for ironboards, printers and engravings (drawings on foil). Ahem: Wood simulation. Ready to get started? Contact us directly! Send us a WhatsApp message to (+34) 647 590 257 or an email to infogester.es for personalized advice.

Extrusion line for 3D monofilament composed of: - Extruder 1 spindle, brand: Bandera, 45 mm diam 25 L/D, motor: 10 hp. With drying hopper: 100 L, master dispenser. With electrical panel and variable speed drive. - Head for 3D monofilament. - 3 stainless steel bathtubs: 2 m. - Stretch: 4 rollers. With variator. - 2-point monofilament thickness gauge. - Winder: 480x500 mm diam. For large coils. - Large reel unwinder and double rewinder for small reels. Ready to get started? Contact us directly! Send us a WhatsApp message to (+34) 647 590 257 or an email to infogester.es for personalized advice.

Reifenhauser RH 241 Single screw 50mm 25D Only extruder there is no cabinet Make an offer ... más información